Our customers say

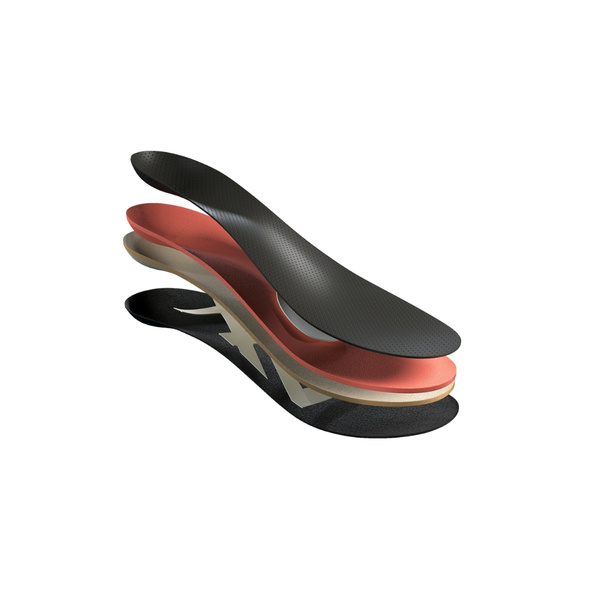

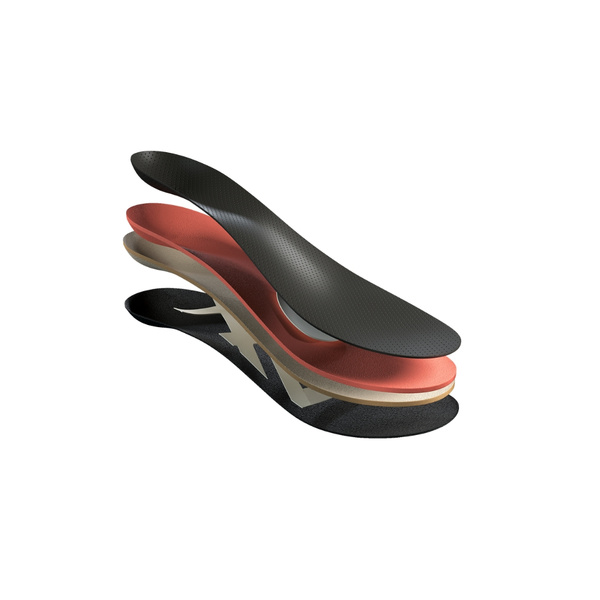

5-Bar System

The 5-Bar System insoles are designed to relieve pressure on the feet, lower legs, knees, hips, and back, provide stability, and help align the body into the correct position. With each use, the insoles mold to the shape of your feet.

Technology

The desired effect and the most important feature of our shoes is providing stability, ensuring that the body’s biomechanics are as optimal as possible and that your feet, knees, hips, and back land in the correct neutral position.